Automatic 9 volt Battery Charger

Good care given to your NiCad batteries will ensure a long life. However, they do need to be handled and charged with special care.

It is therefore important to first discharge the NiCad to 1 Volt per cell, ensure that the battery is discharged, and then start the charge cycle.

recommend a charge current of 1/10th the capacity for a duration of about 15 hours uninterrupted.

In reality, we learn some hard lessons when we forget to switch the charger off after the 15 hours and find that one or more cells inside the battery no longer

accept a charge. That is the very reason that the circuit above is fully automated.

The only thing to do is connect the battery and press the 'Start' button. When the discharge cycle is finished the circuit switches over to charge for 15 hours. After

the 15 hours the circuits maintains a trickle charge to keep the battery 'topped-up

Before I go into the schematic details I like to explain some of the component descriptions in the schematic. Jan Hamer lives in the Netherlands and so the circuit

details are based on european standards.

120E, 150E, etc. The 'E' just stands for Ohms so 120 ohm, 150 ohm. The original circuit specified the HEF type of cmos IC's which are not readily available in

most of Canada. So just get any other type of CMOS chip like the MC4011, MC4020, MC4047 from Motorola. Any other type will do fine too. The BC548B is

replaceble by a NTE123AP (NOTE: make sure it is the 'AP' type, the regular NTE123A is a total different transistor), ECG123AP, and the 2N3904 will work

also. Watch for the correct pin locations since the BCE may be reversed with this european type. The LM317T is a TO-220 type and replaceble with a ECG956

or NTE956. The LM339N can be replaced with a ECG834 or NTE834

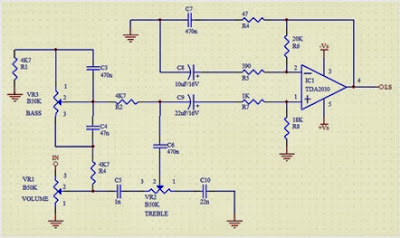

Although this circuit looks quite impressive and maybe a bit difficult it is certainly not difficult to understand. The circuit needs to be hooked-up to a DC supply

voltage of between 16.5 and max 17.5 volt, otherwise the CMOS IC's will go defective. Because I didn't feel like to design a seperate powersupply for this circuit

I connected it to my fully adjustable bench top powersupply.

First we connect a 'to-be-charged' 9-volt nicad battery to the appropriate connections. Then hook it up to the powersupply. Upon connection the 1nF capacitor

starts up the two RS Flip-Flops formed by IC1a, IC1b, IC1c, IC1d, and pulls pins 3 and 10 'high' and pins 4 and 11 'low'. The clock pulses are created by the free-

running multivibrator IC4. IC4's frequency is determined by the 10uF capacitors, the 220K resistor and the 100K trimpot. The clock runs continuesly but the

counter behind, IC5, is not counting yet because pin 11 (the master-reset) is kept high. When the 'START' button is pressed, output pin 4 from IC1a goes high

and biases TR4, which is made visible by the Red LED (D9) which remains lit. The NiCad is now being discharged via this transistor and the 100 ohm resistor.

The 10K trimpot (at the right of the diagram) is adjusted in such a way that when the battery voltage dips below 7 volt, the output of IC3 goes LOW and the

output pin 11 of IC1a HIGH. At hte same time the output pin 10 of IC1d goes LOW, and the red LED turns off.

Because output pin 11 went HIGH the green LED (D8) lights up and at the same time the voltage level rises causing the battery to be charged. The charge-

current is determined by the 120 ohm, 150 ohm, and the trimpot of 1K, at the right side of IC2. Actually we could have used one resistor, but the output voltage

of different brands for IC2 may differ, by about 1.25 volt.

Because the charging current is devided by value of the resistors, with the trimpot the current can be adjusted to the correct value of your own 9-volt NiCad. (In

my case, the battery is a 140 mA type, so the charge current should be adjusted for 14 mA (c/0.1).

At the same time the LOW of output pin 10 from IC1d starts the counter of the clock. On pin 9 of IC5 appear pulses which light up the red LED. This is

implemented for two reasons, the clock-frequency can, with the 100K trimpot, be adjusted to the correct value; the red LED has to come ON for 6.59 seconds

and for the same duration going OFF and except for that fact the green LED, who indicates the charge current, can be checked if the total charge-time is correct.

When the counter has reached 8192 pulses ( x 6.59 = 53985.28 sec = 14.99 hours) the output pin 3 of IC5 goes high again, transistor Tr1 activates and resets the

two flip-flops to the start position.

The charging process stops and goes over to trickle charge via the 10K resistor and the D2 diode and keeps the battery topped-up.

The adjustments of the project are really very simple and nothing to worry about. Turn the walker of the 10K pot in the direction of the 12K resistor, ground

connection point of 10K resistor/diode D2, like the adjustment pin of IC2, apply a voltage of 7-volt to the battery connection terminals, switch the power ON and

slowly turn the pot backward until the greeen LED starts to light up. Switch OFF the power and take away the connections you made to make the adjustment.

Insert an amp-meter between the battery and the output connection and again switch the power ON. The battery will, in case it is not completely empty, totally

discharged (to a safe level) and as soon as the 7 volt margin is reached goes over to the charge cycle. The charge current is at this time adjusted via the 1K

trimpot (which is connected in series with the 150 Ohm resistor and in parallel with the 120 ohm resistor) accurately to the desired value.

Addendum: It is strongly recommended to include small 100nF ceramic capacitors over the powersupply lines feeding EACH CMOS IC to keep possible

interference to a negliable value.

Jan Hamer

Copyright © 1995 - 2001 Tony van Roon

Comments

Post a Comment